Introduction

Dynamic simulation of chemical processes is one of the key tools to optimize performance and design control systems. Ethanol, as an important substance in various industries, is usually obtained in a mixture with water. Its separation faces challenges due to the formation of azeotrope between water and ethanol.

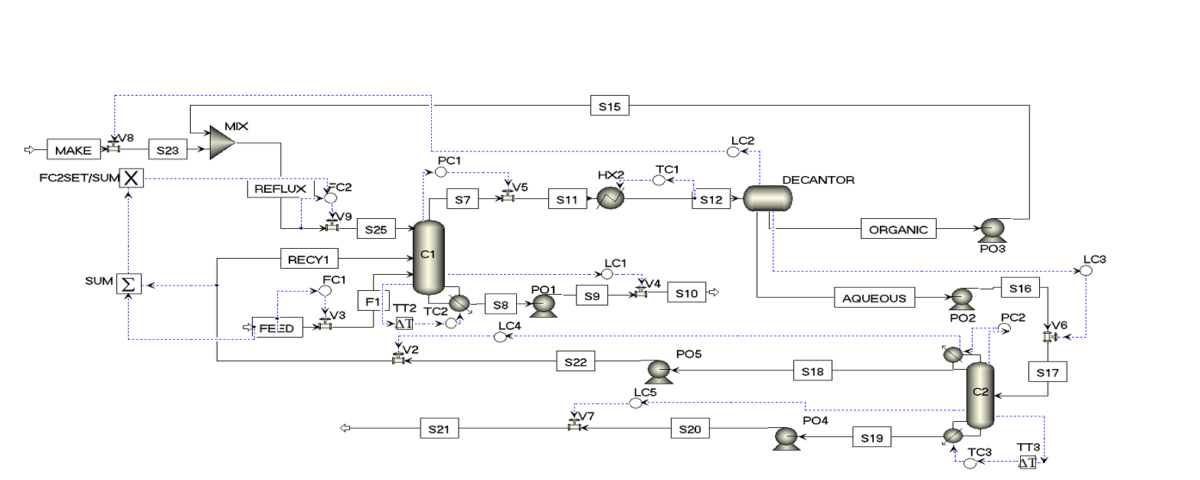

To overcome this challenge, a heterogeneous dehydration method using a tertiary solvent is employed. In this project, the dynamic simulation of heterogeneous ethanol dehydration process using Aspen Plus Dynamics software is described. This project aims to analyze the dynamic behavior of the process and optimize the operating conditions and control systems.

Simulation of Process Dynamics

1. Transition From Stable to Dynamic State

At this stage, the stable model, which was simulated in Aspen Plus software (version 12), was transferred to Aspen Plus Dynamics software. The transition from steady state to dynamic means that instead of analyzing the process in a steady state without time changes, now the behavior of the process is examined over time and under different operating conditions. This transition includes the conversion of stable parameters to time-dependent parameters and the new definition of equipment and control systems.

2. Definition of Equipment and Dynamic Variables

The main process equipment including distillation columns (azeotrope column, and solvent recovery column) and heat exchangers were dynamically modeled in full detail. Each column was defined based on the number of trays, height, diameter, and other dynamic characteristics such as heat capacities and reservoir volumes. Also, the input and output flows and key variables such as temperature, pressure and concentrations were dynamically defined and adjusted.

3. Definition of Controllers and Control System

To maintain optimal operating conditions and prevent unwanted fluctuations, advanced control systems were included in the dynamic model. PID controllers were defined to control temperature, pressure and flow rates. The initial settings of the controllers were done. And then their performance was simulated and optimized under different operational conditions. These control systems help the process remain stable in the face of sudden changes or abnormal conditions.

4. Analysis of Different Scenarios

Simulation of process dynamics provides the possibility of analyzing the behavior of the system in different conditions and different scenarios. In this part of the simulation, sudden changes in the input flow rate, temperature and pressure fluctuations and other factors affecting the process performance were modeled. Analysis of these scenarios provided valuable information about system stability, response time, and controller performance.

5. Management of Time and Operating Conditions

One of the important aspects of dynamic simulation is time management and monitoring of operating conditions over time. Aspen Plus Dynamics software allows the process to be simulated at different time intervals. And the results should be presented graphically and numerically in the form of changes in key variables over time. This analysis helps to better understand the effect of time changes on the performance of the entire process as well as the stability and efficiency of the control systems.

Analysis of Dynamic Simulation Results

Dynamic simulation results include graphs of changes in temperature, pressure, concentrations, and other important variables over time. These diagrams show the behavior of the system in the face of various changes. Some of the important results are:

System stability: The results showed that the dynamic system is able to maintain stability even in the conditions of sudden changes using appropriate controllers.

Response time: the system quickly reacts to input changes and operating conditions quickly return to the desired state.

Performance of the controllers: the designed controllers had a good performance and were able to control fluctuations and adverse changes well.

Conclusion

This report showed that dynamic simulation of heterogeneous ethanol dehydration process using Aspen Plus Dynamics software is a powerful tool for better understanding of system behavior and optimization of operating conditions. The use of benzene solvent in this process provided favorable results. And the control systems were able to ensure the stability and efficiency of the process under different conditions. It is suggested to use this type of simulation in operational stages to predict and prevent possible problems. And the control systems are continuously optimized to maintain the optimal performance of the process.

Resources

.Distillation Design and Control Using Aspen Simulation. John Wiley & Sons. Luyben, W. L. (2013)

Related Projects

SANILCO has successfully implemented several projects in the field of heterogeneous ethanol dehydration, including:

1. Simulation of Heterogeneous Ethanol Dehydration Process With Aspen Plus Software

In this project, the simulation of heterogeneous ethanol dehydration process was carried out using Aspen Plus version 10 and 12 software based on the methods and data of the article, and the operational parameters were analyzed and optimized.

2. Simulation of Ethanol Dehydration Process Using UNIQUAC Model in Aspen Plus

After investigating and simulating the ethanol dehydration process using the NRTL model, the results of which were analyzed. In this project, we have investigated this process using UNIQUAC thermodynamic model. Considering the non-ideal interactions between the mixture components, this model shows higher accuracy in predicting the phase behavior and separation of mixtures, especially in more complex conditions.

3. Simulation and Optimization of Ethanol Separation From Water in Aspen Plus

In this research, the heterogeneous ethanol dehydration process has been simulated and optimized using Aspen Plus software with the aim of generalizing it to an industrial unit. The main goal of this project is to reduce operating costs and increase energy efficiency, considering the actual conditions of the industrial unit.

In this project, improving the simulation of heterogeneous ethanol dehydration process using data regression to increase simulation accuracy and achieve more optimal results has been done in Aspen Plus software, and analyzed and optimized operational parameters.

Dynamic Simulation of Heterogeneous Ethanol Dehydration

In this project, the dynamic simulation of heterogeneous ethanol dehydration process has been done using Aspen Plus software. This project has additional explanations.