Introduction

Heavy paraffins in diesel fuels are one of the main concerns for oil refineries. Since these compounds have high melting point values, they crystallize when the fuel is subjected to low temperatures, leading to wax formation in filters.

To overcome this issue, ExxonMobil developed a new process similar to hydrocracking called catalytic dewaxing. This process utilizes dual-function selective catalysts such as Pt/ZSM-5 for the isomerization or decomposition of heavy paraffins through selective isomerization and cracking reactions.

To quantitatively assess the process’s impact on the cold flow properties of diesel, the cloud point, which is the highest temperature at which the first wax crystals form, is used as a product specification. There is strong evidence that an increase in hydrodewaxing conversion results in a decrease in the cloud point of the diesel product. However, an increase in process severity favors cracking stages and may lead to an increase in diesel yield losses.

Catalytic Dewaxing in Refinery Industry

Two types of catalytic dewaxing processes are utilized in the refinery industry:

– Selective Cracking Dewaxing (MDDW)

– Selective Isomerization Dewaxing (MIDW)

The oldest process, MDDW, reduces the cloud point of intermediate distillates by selectively breaking down heavy paraffins into smaller ones. The main drawback is the high yield loss of diesel at high conversions, which can be mitigated by using feedstock with a higher final boiling point to balance diesel loss with cracking conversion. MIDW supports the isomerization pathway in the reaction mechanism, with a lower reduction in diesel yield compared to MDDW.

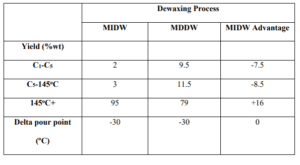

Performance Comparison between MDDW and MIDW Processes

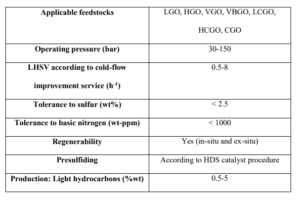

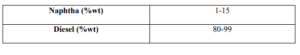

The table below presents a comparison of performance between the MDDW and MIDW processes.

It is noteworthy that no improvement in the pour point was observed for the MDDW process. However, the amount of lighter products is significantly higher than that observed for the MIDW operation. Due to the negative impact of nitrogen and sulfur compounds on the dewaxing activity, the feedstock must first be treated with water. Consequently, placing hydrotreater and hydrodewaxer catalyst beds in one unit or in series is a common method in oil refineries.

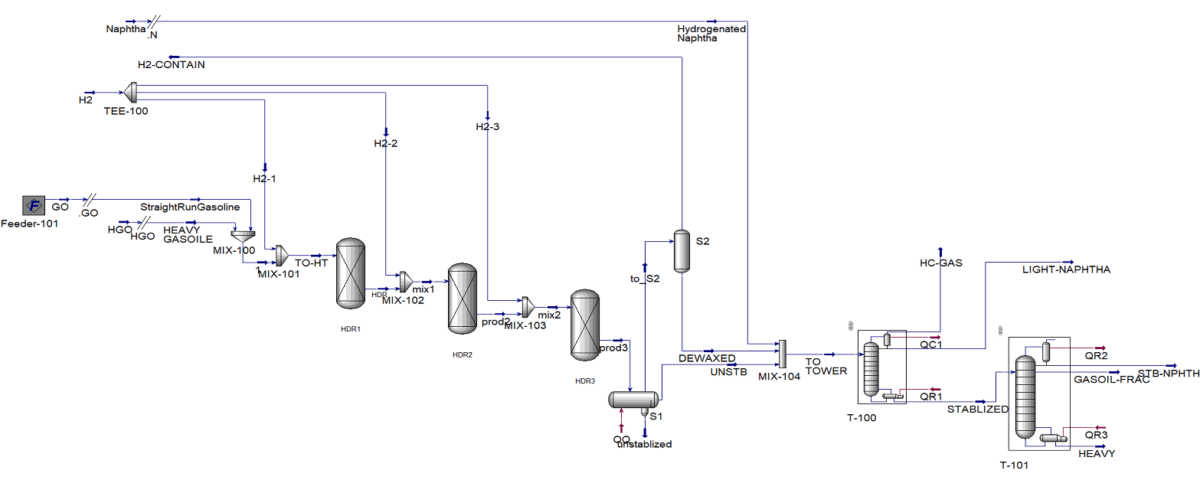

Schematic Representation of the Catalytic Dewaxing Process

The schematic representation of the catalytic dewaxing process in multi-stage and series configurations is illustrated in the following figures.

The configuration shown in the first figure is typically executed when an existing HDT unit is available, with the selective dewaxing catalyst being loaded as an additional bed. On the other hand, when the demand for diesel with improved cold flow properties is seasonal, i.e., only during winter, the configuration depicted in the second figure is usually implemented, where the output stream from the HDT reactor is routed to the hydrodewaxing unit.

Operational Conditions and Feedstock Range

The most common range of operational conditions and types of feedstock used for industrial catalytic dewaxing operations is presented by Rakoczy and Morse (2013), as shown in the table below.

Dewaxing Catalysts

Dewaxing catalysts consist of three main components:

– Acidic component for cracking functions (zeolites, aluminosilicates, alumina oxides)

– Dehydrogenation-hydrogenation component (metals such as nickel, cobalt, platinum, palladium, molybdenum, tungsten) and binder (alumina or aluminosilicates)

This study considers the catalytic dewaxing process using a dual-function catalyst containing nickel.

Modeling

The aim of this study was to enhance the catalytic dewaxing process using modeling techniques.

This model was developed by considering the thermodynamic and kinetic laws of the process and the interconnection of processes in the adjacent system “reactor column – stabilizer.”

Utilizing the model provides recommendations for controlling operational conditions depending on the feedstock composition. This ensures optimal product yield and compliance with standards concerning cold flow properties. It also offers recommendations for reducing corrosion in equipment and pipelines in the dewaxing industrial unit due to the complete removal of hydrogen sulfide from the stabilized naphtha, which is one of the products.

Optimization of Reactor Input Temperature in Dewaxing Using the Developed Model

One of the key properties of diesel fuel that improves with the catalytic dewaxing process is the cold filter plugging point (CFPP). The CFPP is defined as the lowest temperature (in degrees Celsius) at which a specific volume of diesel fuel passes through a standard filtration device within a certain time under specific cooling conditions. This test provides an estimate for the lowest temperature that a fuel can achieve without issues.

Using the developed mathematical model, the input temperature of the reactor was optimized so that the CFPP of the product was equal to -26°C for the winter mode.

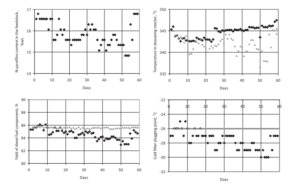

Explanation of Graphs

As observed, the feed composition in terms of n-paraffin content varied between 14.8% and 16.79% by weight. Here, the reactor input temperature was maintained within a narrow range of 342.5°C to 347.5°C without accounting for the variable feed composition.

At the optimal temperature calculated using the mathematical model, the CFPP of the product met the required specifications (CFPP equal to -26°C) under high product yield performance of 85-86%. The optimal temperature for varying feedstock compositions is 4 to 8 degrees Celsius lower than the current value.

Conclusion

To address wax formation, a catalytic dewaxing method was developed using selective dual-function catalysts such as Pt/ZSM-5 for isomerization or decomposition of paraffins.

The developed mathematical model also enables the calculation of material and thermal balances within the reactor with acceptable accuracy, as well as estimating the impact of varying technological conditions on process efficiency. The model’s sensitivity to changing feedstock compositions allows the process to be executed under optimal conditions for a specific type of feedstock as per the desired CFPP and performance.

Modeling and Simulation of Diesel Reactor Catalytic Dewaxing in Aspen HYSYS

In this project, the catalytic dewaxing process of diesel reactors was simulated in Aspen HYSYS software.