Introduction

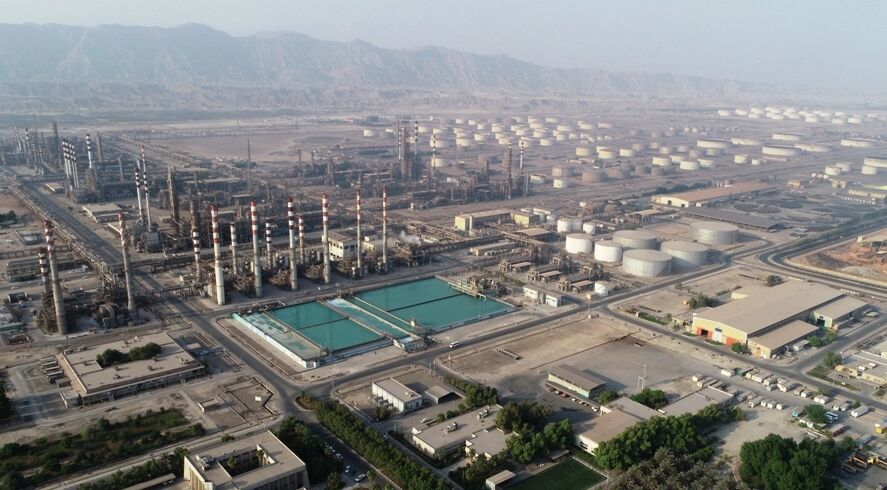

The BANDAR ABBAS Refinery is one of the largest and most significant industrial projects in the oil and gas industry of Iran, located in HORMOZGAN Province near BANDAR ABBAS, with a daily crude oil processing capacity of 300,000 barrels. The refinery commenced operations in 1998 and plays a crucial role in supplying fuel and petroleum products for the country. Considering its strategic geographical position next to the Persian Gulf, which allows easy access to open waters and commercial ports, this facility has become a key center for the export and import of petroleum products.

The BANDAR ABBAS Refinery pursues multiple goals, including meeting domestic needs for refined products and fossil fuels.

CCR Unit in the Persian Gulf Refinery

The CCR (Continuous Catalyst Regeneration) unit is a key component in producing gasoline and other petrochemical products at the Persian Gulf Refinery. This unit employs advanced technologies to optimize the conversion of crude oil into high-quality products. The main focus of the CCR unit is to increase efficiency and reduce emissions. Given the global demand for quality products and environmental regulations, the significance of designing the CCR unit with modern criteria and optimizing processes becomes evident.

Modern Technologies in Optimizing the CCR Unit

The use of modern technologies is one of the most crucial factors in optimizing the CCR unit. This section will explore advanced techniques and tools such as machine learning algorithms, data mining, and precise process simulations that can help predict and better control the operational conditions of the unit. New technologies in advanced catalysts and energy recovery systems will also be analyzed to improve efficiency and reduce operational costs. Optimizing processes using these technologies can lead to reduced downtime and increased production of high-quality products.

Process Analysis and Simulation

To optimize the CCR unit, precise analysis and simulation of chemical processes are essential. This section will discuss the importance of using simulation software such as Aspen HYSYS and COMSOL to analyze the behavior of the CCR unit. These software tools allow for accurate modeling of processes, helping to identify optimal points and evaluate various operational scenarios. By simulating inputs and operational conditions, experts can predict system behavior under different scenarios and achieve optimal designs. These analyses also aid in evaluating catalyst performance and its effects on product quality, thus maximizing the unit’s efficiency.

Process Improvement and Optimization

This section will emphasize the importance of reforming and improving operational processes in the CCR unit. By identifying weaknesses and implementing corrective actions, productivity can be increased. This includes improving operational conditions, continuous monitoring of equipment performance, and optimizing equipment downtime. Implementing process management and preventive maintenance strategies can help prevent problems and extend equipment lifespan. Additionally, continuous upgrading of protocols and operational guidelines based on data obtained from previous simulations and analyses facilitates processes and reduces costs.

Energy Management and Emission Reduction

Energy management and emission reduction are other critical aspects of optimizing the CCR unit. This section explores various solutions that can help reduce energy consumption and the unit’s environmental impact. This includes the use of heat recovery systems, optimizing water consumption, and utilizing renewable energy sources. By reducing pollutant emissions and minimizing negative environmental impacts, the Persian Gulf Refinery can achieve sustainable development goals. Furthermore, improving production processes and reducing energy consumption contribute to optimizing operational costs and enhancing economic efficiency.

Process Overview

The CCR (Continuous Catalyst Regeneration) unit process at the Persian Gulf Refinery is designed to maximize production efficiency and quality of gasoline and other petrochemical products. One of the remarkable features of this unit is its ability to continuously regenerate catalysts, which helps to extend catalyst life and reduce operational costs.

In this process, catalysts are transferred to a separate section after a period of use, where they are reactivated using controlled temperature and atmosphere. This process ensures that the quality of the produced products remains consistently high and prevents the accumulation of waste materials. Additionally, after the reaction and product separation, waste gases and byproducts are effectively managed to minimize environmental impact. Ultimately, the final products are prepared with desirable characteristics for use in domestic and international markets. Thanks to this advanced and efficient process, the CCR unit at the Persian Gulf Refinery is recognized as a vital source for meeting energy and chemical needs.

The optimization process of the CCR (Continuous Catalyst Regeneration) unit at the Persian Gulf Refinery, through innovative conceptual design, aims to increase efficiency, reduce costs, and improve the quality of chemical and petroleum products. This process involves using advanced and up-to-date technologies along with in-depth data analyses and complex simulations, enabling engineers to identify weaknesses and optimization potentials.

In this context, the redesign of processes and equipment is carried out in such a way that heat and mass transfer are optimized, equipment downtime is reduced, and ultimately productivity and catalyst performance are enhanced. Furthermore, with the help of machine learning algorithms and advanced control systems, operational conditions are monitored in real time, and adjustments are automatically made to maintain the highest performance levels. Effective energy management and heat recovery from processes also contribute to reducing costs and environmental impacts. Ultimately, this innovative design not only enhances the quality of final products but also establishes a unique model for future projects in the refinery industry.

Conclusion

By utilizing modern technologies and optimizing processes, it is expected that the production of high-quality products will increase while production costs will decrease. Additionally, improving equipment performance and reducing emissions will enhance environmental conditions and contribute to local economic prosperity. Ultimately, the future outlook for this unit, focusing on innovation, continuous optimization, and adherence to sustainable development principles, will position the Persian Gulf Refinery as a model in the refinery industry at both national and global levels.

To enhance the performance and efficiency of the benzene evaluation unit at the BANDAR ABBAS Refinery, ANILCO has undertaken comprehensive simulation and optimization studies on the key equipment and processes of this unit. These studies include:

– Pre-feasibility and benzene recovery at the Persian Gulf Star Oil Refinery using Comfar.

– Simulation and optimization of benzene recovery at the Persian Gulf Star Refinery using Aspen HYSYS.

– Optimization of the CCR unit at the Persian Gulf Refinery through innovative conceptual design.

The optimization of the CCR unit at the Persian Gulf Refinery, with innovative conceptual design, has been simulated in Aspen HYSYS version 14.