Aspen HYSYS Training Course

مهر ۱۱, ۱۴۰۳

Aspen Custom Modeler Software Training

مهر ۱۵, ۱۴۰۳Introduction

The company “Chemical Engineering Projects” (CHEMENGPROJ) leverages years of experience and expertise to provide services in the oil, gas, and petrochemical sectors. With a team of experienced engineers and specialists, we undertake extensive projects in the design, simulation, and optimization of industrial processes. By focusing on advanced technologies and powerful software, we deliver innovative and optimized solutions to the complex challenges of these industries.

CHEMENGPROJ Services

-

Design and Simulation of Oil and Gas Processes

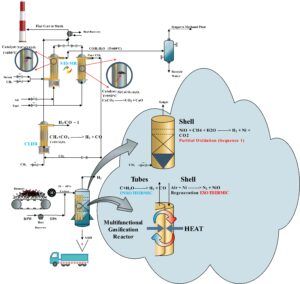

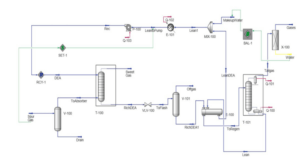

The design and simulation of industrial processes, especially in the oil and gas industries, is one of the most complex phases of engineering projects. At CHEMENGPROJ, we use advanced software like Aspen Hysys and Aspen Plus to accurately simulate complex processes in refinery, petrochemical units, and oil and gas pipelines. These simulations include the design of separation units, gas sweetening units, heat exchangers, and turbines.

- Pipeline Simulation: Using OLGA software, we model multiphase flows in pipelines. This software allows our engineers to analyze pressure, temperature, and flow variations accurately, providing optimal designs.

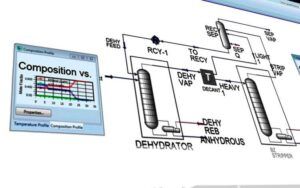

- Process Unit Simulation: Aspen Plus and Aspen Hysys enable the simulation of complex chemical processes in petrochemical and refinery units. We can model and optimize the performance of heat exchangers, reactors, and distillation columns with high precision.

These services empower us to provide optimal and efficient solutions to improve performance and reduce operational costs for our clients.

-

Front-End Engineering Design (FEED)

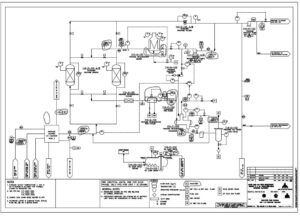

At CHEMENGPROJ, we assist companies in the oil and gas industries with Front-End Engineering Design (FEED) services to ensure their projects are designed from the ground up according to international standards. These services include preliminary process design, equipment selection, and the preparation of P&ID and PFD diagrams. By utilizing software tools like Aspen Custom Modeler, we convert complex processes into mathematical models and provide designs that ensure energy optimization and increased efficiency.

- Optimal Equipment Selection: One of the most critical steps in conceptual engineering is selecting the right equipment. Through detailed analyses, we select equipment that aligns with process needs and economic constraints.

- Preparation of P&ID and PFD Diagrams: P&ID (Piping and Instrumentation Diagrams) and PFD (Process Flow Diagrams) are among the most important design documents for an industrial project. Our engineering team meticulously prepares these diagrams and updates them throughout the project, adhering to international standards.

-

Optimization and Specialized Consulting

Process optimization at every stage of project design and execution is essential, as it can significantly reduce costs and increase efficiency. CHEMENGPROJ provides optimal solutions for the oil, gas, and petrochemical industries through advanced modeling tools and performance data analysis.

- Economic Analysis and Cost Optimization: Using tools like Aspen Economic Evaluation, we conduct economic analyses and calculate investment and operational costs. These analyses help our clients make informed decisions regarding investments in their industrial projects.

- Optimization of Unit Performance: By executing optimization projects in various refinery and petrochemical units, significant improvements in overall unit performance can be achieved. We model processes and analyze operational data to identify optimal points in the processes and suggest practical solutions for increasing efficiency and reducing costs.

-

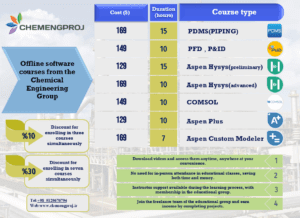

Training in Industrial Software

In today’s world, the ability to utilize specialized software is an essential skill for engineers. At CHEMENGPROJ, we offer comprehensive training courses for software such as Aspen Hysys, Aspen Plus, COMSOL, and other applications related to the oil and gas industries. These courses are available both online and in-person, aimed at enhancing engineers’ capabilities in using these tools effectively.

- Practical Training: In these courses, we not only cover theoretical aspects but also address and solve real project problems. This approach allows participants to gain a deeper understanding of how to apply these software tools in industrial projects.

- Online and In-Person Courses: Our courses are offered in both online and in-person formats to ensure easy access to training for all engineers and students across the country.

Specialized Software at CHEMENGPROJ

CHEMENGPROJ utilizes a suite of powerful software for the design, simulation, and optimization of industrial processes. These tools enable us to achieve cost reduction and increased efficiency at every stage of our projects. Some of the software we use in our projects includes:

Aspen HYSYS and Aspen Plus

These two software applications are among the most widely used tools in chemical engineering, extensively employed in comprehensive simulations of chemical, oil, gas, and petrochemical processes. Aspen HYSYS and Aspen Plus are particularly useful in process design, oil refining, gas processing, and petrochemical production. These applications offer extensive capabilities for modeling, designing, and optimizing industrial units, enabling engineers to simulate and analyze complex processes with high accuracy.

MATLAB and FORTRAN

These two tools are primarily used for performing complex numerical calculations and mathematical modeling. MATLAB provides extensive features for solving engineering problems, including optimization methods, data analysis, and differential equations, playing a crucial role in the design of industrial processes. FORTRAN, known for its high computational power and accuracy in mathematical modeling, is widely used in engineering projects requiring heavy processing.

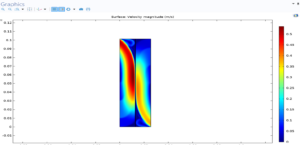

Fluent and COMSOL Multiphysics

These two software applications are used for CFD (Computational Fluid Dynamics) simulations and the analysis of various physical phenomena such as heat transfer and multiphase flows. Fluent is specifically designed for simulating fluids and complex flows in industrial systems, while COMSOL enables multiphysics analysis, allowing engineers to simultaneously simulate fluid mechanics, heat transfer, and other phenomena.

Gambit

Gambit is a powerful tool for meshing and preparing complex geometries for analysis and simulation in CFD software like Fluent. This software enhances the accuracy and reliability of industrial simulation results by offering various capabilities for designing and defining computational grids.

CHEMCAD

This software is a comprehensive tool for simulating chemical processes across various industries. CHEMCAD provides complete facilities for designing and simulating process flows, modeling equipment, and conducting thermal and chemical analyses in industrial systems such as oil, gas, and petrochemicals.

Petro-SIM

Petro-SIM is an advanced software for simulating and optimizing refinery and petrochemical processes. Utilizing precise and sophisticated models, this software aids in analyzing and optimizing the performance of refinery units, enabling users to maximize the efficiency of production processes.

OLGA

This software is utilized for simulating and analyzing multiphase pipeline flows. OLGA can simulate the flow of oil, gas, and water in long and complex pipelines, enabling engineers to evaluate optimal fluid transfer conditions.

ANSYS

ANSYS is a powerful software for engineering analysis and simulating industrial processes. This tool can analyze fluid flows, heat transfer, and solid mechanics, enabling engineers to thoroughly investigate and optimize the performance of industrial equipment and systems.

gPROMS

gPROMS is a specialized software for simulating process dynamics and optimizing industrial units. This tool is particularly useful in the design and optimization of production and petrochemical units, helping engineers to manage and optimize complex processes with high precision.

DWSIM

DWSIM is an open-source process simulation software primarily used for simulating oil and gas processes and chemical production. With a user-friendly interface and high flexibility, this software is suitable for small and medium-sized projects.

OpenFOAM

OpenFOAM is an open-source tool for CFD simulations and analyzing complex phenomena in industrial systems. This software offers extensive capabilities for simulating complex flows, heat transfer, and other physical phenomena in chemical processes.

POLYMATH

POLYMATH is a specialized software for solving differential equations and mathematical models related to chemical engineering and chemical processes. This tool enables engineers to quickly and accurately solve complex mathematical problems and process models.

ProMax

ProMax is used for the accurate simulation of gas and oil processes, including gas refining and sweetening, as well as separation processes. This software is highly effective in optimizing refinery units and increasing the efficiency of equipment.

Autodesk AutoCAD P&ID

Autodesk AutoCAD P&ID is utilized for designing Piping and Instrumentation Diagrams (P&ID). This tool allows engineers to graphically and precisely illustrate process designs and clearly depict the connections between different equipment and instruments.

Aspen EDR (Exchanger Design & Rating)

This software is used for designing and evaluating heat exchangers. Aspen EDR provides precise tools for analyzing and optimizing heat exchangers, helping engineers improve the performance of these systems.

These tools help us model and optimize complex industrial processes with high accuracy and speed. Each software is selected based on the specific needs of oil, gas, and petrochemical projects to achieve the highest quality and efficiency in the final output.

Successful Projects

CHEMENGPROJ has successfully executed numerous projects in the oil, gas, and petrochemical industries over the years, relying on specialized knowledge and advanced chemical engineering software and technologies. These projects demonstrate our capability to face various challenges and provide effective solutions for optimizing processes and reducing costs. Some of our prominent projects include:

Gas Sweetening Unit Simulations

CHEMENGPROJ successfully executed several simulation and optimization projects for gas sweetening units in major refineries across the country. Utilizing Aspen Hysys and Aspen Plus software, we modeled the sweetening processes to reduce energy consumption and enhance operational efficiency. These projects included a detailed analysis of absorption and separation processes for acidic gases such as CO2 and H2S, resulting in improved economic and technical performance of the refineries.

Optimization of Oil and Gas Pipelines

In modeling and optimizing oil and gas transmission pipelines, CHEMENGPROJ improved transfer processes and reduced operational costs using advanced software like OLGA and PipeSim. These projects included simulating multiphase flows in long pipelines and optimizing operational parameters to reduce pressure drop and increase transfer capacity. For instance, in a significant pipeline project between refineries and oil fields, we achieved a considerable reduction in energy consumption through precise modeling.

Heat Exchanger Design and Optimization

Another prominent project by CHEMENGPROJ involved the design and optimization of heat exchangers. Using Aspen EDR and HTRI software, we were able to enhance the performance of heat exchangers in refining and petrochemical units. These projects included assessing and optimizing heat exchangers to reduce thermal losses and increase energy efficiency. The results of these optimizations led to decreased energy costs and increased equipment lifespan.

Simulation and Optimization of Petrochemical Units

In the petrochemical sector, CHEMENGPROJ has successfully completed numerous projects, including the simulation and optimization of olefin, polymer, and various chemical production units. By employing CHEMCAD and ProMax software, we optimized complex production processes and increased production capacity. For example, in a polyethylene production optimization project, operational condition changes were proposed that led to increased production efficiency and reduced energy consumption.

Environmental Assessment and Industrial Process Optimization

One of our successful projects focused on the environmental assessment of industrial processes aimed at reducing emissions and improving the environmental performance of units. Utilizing tools like MATLAB and COMSOL Multiphysics, we calculated the emissions of industrial pollutants and provided solutions for their reduction. These projects significantly contributed to industries’ adherence to environmental standards and reduced harmful environmental impacts.

Engineering Document Design for New Refinery Units

CHEMENGPROJ has also been involved in designing and preparing engineering documents for new refinery and petrochemical units. Utilizing AutoCAD P&ID and Aspen HYSYS software, we meticulously designed engineering documents including Process Flow Diagrams (PFD) and Piping and Instrumentation Diagrams (P&ID), which reduced operational errors and facilitated the startup process.

Why Chemical Engineering Projects?

With over a decade of experience in executing complex engineering projects in the oil, gas, and petrochemical industries, Chemical Engineering Projects (CHEMENGPROJ) is recognized as one of the leading companies in this field. We continually strive to provide efficient and innovative solutions to industrial challenges by leveraging cutting-edge technologies and advanced engineering software. Our goal is to enhance productivity, improve process performance, and reduce operational costs for our clients.

-

Specialized and Experienced Team

- Our engineering team comprises individuals with diverse specializations and years of experience in the oil, gas, and petrochemical industries. This team possesses extensive technical knowledge and expertise, enabling us to analyze industrial issues accurately and offer suitable solutions. Moreover, we utilize the best simulation and modeling software for designing, optimizing, and executing projects. Each team member is carefully selected to ensure the highest level of performance and expertise at every project stage.

-

Commitment to Quality and Timeliness

- Quality is our primary commitment in every project. We fully understand that each project requires not only accurate execution but also timely completion according to a specified schedule. From conceptual design to the full startup of industrial units, our team works meticulously and pays attention to detail at all stages. The use of advanced project management tools and process optimization methods allows us to complete projects on time while adhering to the highest quality standards.

-

Utilization of Advanced Technologies

- CHEMENGPROJ seeks to improve efficiency and reduce costs in all its projects by utilizing the latest technologies and engineering software. From simulating complex processes to designing optimized systems, we remain aligned with state-of-the-art technologies and have the capability to provide innovative solutions. Software such as Aspen HYSYS, Aspen Plus, MATLAB, and COMSOL allows us to deliver precise analyses of industrial processes and implement effective optimizations.

-

Customer-Centric Approach

- Our customers are at the heart of all our activities. We closely collaborate with clients to thoroughly understand their needs and challenges, providing tailored and customized solutions for each project. Our aim is to build long-term relationships with customers through high-quality service and tangible results. Our commitment to providing efficient and accurate solutions ensures complete customer satisfaction in every project.

-

Successful Experience in Major Projects

- Our successful projects in large oil, gas, and petrochemical industries showcase our capability and expertise in managing and executing industrial projects with numerous complexities. We have achieved successful outcomes in various national and international projects by utilizing our professional team and optimization methods. From simulating and designing refinery units to optimizing pipelines and transmission systems, our experience has become a strong foundation for the success of new projects.

List of Educational Software Courses and Project Request

For purchasing the above educational products and requesting project execution, please proceed through the link below.

4 Comments

What are the advantages of using advanced software in oil and gas and petrochemical projects?

hello

These softwares are used for improved planning, data analysis, risk management, resource management and simulation and optimization, which generally improve the process.

Thank you for introducing important software

good luck