Caustic Recovery

مهر ۱۱, ۱۴۰۳

Sulforex

مهر ۱۱, ۱۴۰۳Introduction

Sour water recovery or sour water treatment is a process that is carried out in order to recover and purify water. Waters that are known as sour water due to chemical imbalance, contamination or the presence of undesirable compounds. Sour water typically refers to water that has a low pH (acidic) and may contain organic matter, oil, and other chemical compounds.

Sour Water Recovery Process Steps

1. Water collection and analysis: First, sour water is collected and chemical analysis is done to determine what types of pollutants and compounds are in the water.

2. Pre-treatment: In this stage, the water is cleaned of coarse particles and suspended pollutants. This step usually involves processes such as screening, settling or filtering.

3. pH adjustment: To treat sour water, it is usually necessary to increase the pH of the water. This is done using alkaline substances such as sodium hydroxide or calcium carbonate.

4. Chemical purification: In this step, chemicals are used to remove organic substances and toxic compounds. For example, oxidation, softening or zeolite processes can be used.

5. Biological treatment: In some cases, biological treatment is also necessary. This process usually involves the use of microorganisms to break down the organic matter in the water.

6. Final filtering: After the above steps, a final filter is used to remove the remaining fine particles and microorganisms from the sour water.

7. Water quality check: After the purification process, the water should be tested to ensure that its quality has reached the standard and is physically and chemically suitable.

Separation of Acid Gases and Hydrocarbons From Water

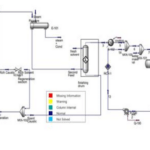

The purpose of this unit is to remove hydrocarbons, H2S and sour compounds from sour water collected from all units. The incoming feed is sour water from unit 102 (maximum 34 t/h) and units 101, 103, 104, 116 and 129 (maximum 6 t/h). Also, the products are purified water to unit 129, sour gas to unit 140 (LPflar) and overflowed hydrocarbons to unit 142 or 143.

This unit has two trains and each one contains a distillation tower that is used to separate sour gas and water. From the sour separated in the distillation tower, it is directed to the LP flare and the purified water is sent to the unit 129. Also, the hydrocarbons in the sour water are separated by the feed drum. and they are directed to off spec tanks or burn pits. The sour water separated in this part is directed to the distillation tower for sweetening. In this unit, a caustic flow line is installed on the tower, which can be used to decompose possible amine compounds with sour water when necessary.

Important Points in the Sour Water Recovery Unit

– The selection of appropriate purification methods depends on the type and amount of pollutants, the volume of sour water, and the final needs of purified water.

– In some cases, the use of new technologies such as nanofiltration, reverse osmosis and ultraviolet radiation treatment will also be useful.

Sour Water Recovery Unit from the Point of View of Energy Consumption in Sarkhes Gas Refinery

Sour water recovery unit is one of the operating units of Shahid Hashminejad Refinery, where LP steam or temperature of 148 degrees Celsius and pressure of 450 kPa is used for the recovery of sour water. In this project, a kettle reboiler is designed and installed in the LP steam path. which, while providing the necessary heat to separate hydrogen sulfide gas from sour water in the stripper tower, will prevent the loss of at least 2.3 tons per hour of LP steam.

In order to design the reboiler, the heat capacity of the reboiler has been calculated by specifying the flow rate of sour water entering the unit in the simulated process with Aspen Hysys software. Then, with this value and LP steam temperature and pressure conditions, the reboiler was designed using Aspen HTFS and TASC software. By carrying out this plan, while preventing the loss of at least 2.3 tons/hour of LP steam in the stripper tower, it will lead to a reduction in fuel consumption by 161 cm/hr in high pressure boilers.

Also, from an economic point of view, reducing fuel gas consumption by about $300 per month will result in a profit of about 36 million tomans for Shahid Hashminejad Gas Refining Company.

Conclusion

Sour water recovery or sour water treatment is a process that is done to recover and purify water. Waters that are known as sour water due to chemical imbalance, contamination or the presence of undesirable compounds. The steps of this process include water collection and analysis, pre-treatment, pH adjustment, chemical treatment, biological treatment, final filtering, water quality check.

But choosing the right methods for regeneration and purification depends on the type and amount of pollutants, the amount of sour water. Also, hydrocarbons are separated by distillation towers.