Description

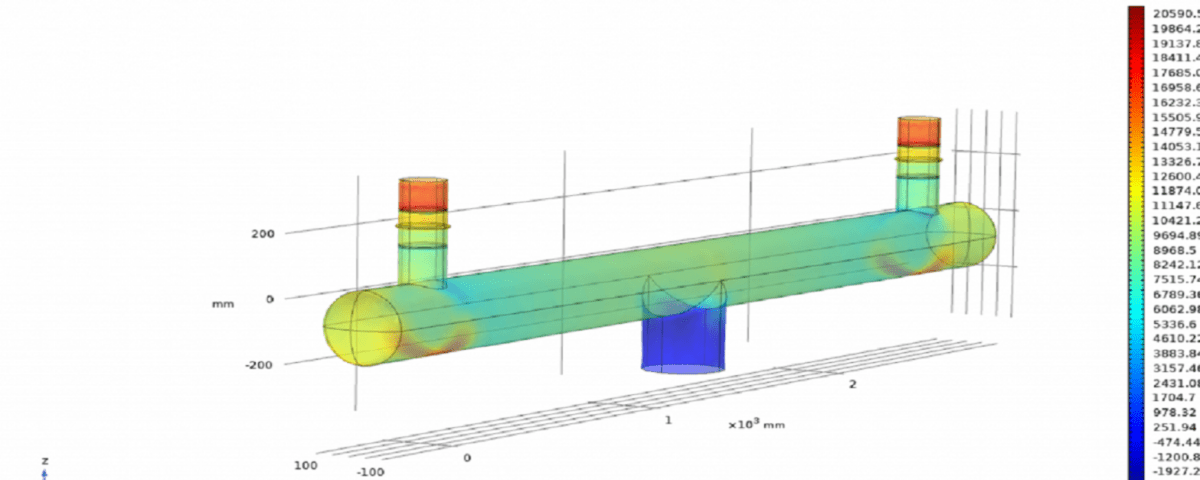

In this project, the corrosion inside the header pipe exiting the cooling tower is simulated with the help of Comsol software. Parameters such as fluid velocity, pressure, stress, etc., which have a great effect on the amount of stress, will be investigated in this simulation. The emulation type of this header is very important.

The simulation is chosen in 3D for the following reasons:

1. Detailed examination of the stress and maximum pressure on the header to calculate the corrosion rate

2. Due to the fact that more corrosion occurs around the inlet flange in the industrial unit, the effect of the weld line and the existing seal between the flanges should be checked.

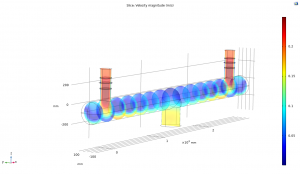

3. Investigating the 3D effect of speed on the header wall

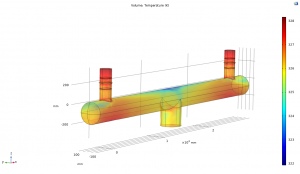

In the software, first select the 3D mode and select fluid physics of turbulent motion along with heat transfer. Therefore, it is required that the type of multi-physics physics is of the no isothermal flow type, so that the changes of these two physics can be solved together.

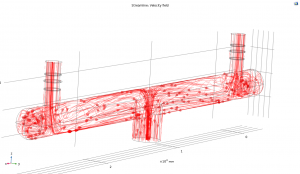

The following images show some of the results.

Volecity

Temperature

Flow Lines