Introduction

Adsorption has gained significant attention in industrial gas separation due to its high efficiency, low cost, and the wide range of available adsorbents. The adsorption process is cyclical, requiring regeneration of the adsorbent after the desired components have been adsorbed. Regeneration typically occurs at reduced pressure, followed by a pressure swing to prepare the adsorbent for the next adsorption cycle. This project focuses on simulating the separation of nitrogen from air using the Pressure Swing Adsorption (PSA) process.

Pressure Swing Adsorption (PSA) for Gas Separation

PSA is a well-established technology used in various industries to produce industrial gases like oxygen, nitrogen, and hydrogen. The process involves separating target components from a carrier fluid (such as air or process streams) using solid adsorbents.

A typical PSA system consists of two or more pressure vessels containing adsorbent material (molecular sieves), along with ancillary equipment like piping, valves, and a control system.

1.Nitrogen Production Using PSA

A Pressure Swing Adsorption (PSA) nitrogen generation system utilizes two towers filled with Carbon Molecular Sieve (CMS). Compressed and conditioned air is passed through these towers alternately. The CMS selectively adsorbs oxygen, allowing nitrogen to pass through.

While one tower is adsorbing oxygen, the other is being regenerated using a portion of the produced nitrogen to desorb the adsorbed oxygen. This process is cyclical, with the roles of the towers being reversed periodically.

The process, while seemingly simple, involves intricate design and construction phases. Precise scheduling of adsorption, regeneration, compression, and discharge is crucial.

Controlling pressure and flow fluctuations is paramount. To achieve this, air and nitrogen buffer tanks are incorporated into the system, enhancing stability and product purity. Typically, the inlet pressure ranges from 7 to 10 bar, with the outlet pressure around 1 bar lower.

Advantages:

- A simple and efficient method for industries that require lower volumes and/or relatively lower purity of nitrogen gas.

- Cheaper than other systems (with similar volume and purity) such as Cryogenic or Membrane.

- Operating these systems is simple, and their maintenance is cheaper.

Disadvantages:

- On average, 10% energy loss in the system due to the CMS material regeneration phase.

- High sensitivity of the produced gas purity based on the quality of the CMS materials used.

- High sensitivity of CMS materials to oil impurities in the inlet air.

- High sensitivity of CMS materials to the flow rate inside the system.

2. Oxygen Production by PSA Method

The method of producing oxygen gas is similar to what was presented above for nitrogen gas, with the difference that in this system, molecular sieve materials specific to this process are also used to adsorb nitrogen molecules and produce oxygen. Also, due to the higher sensitivities regarding the potential hazards of accumulation and applications of oxygen gas, higher operational standards are also used for working with such equipment.

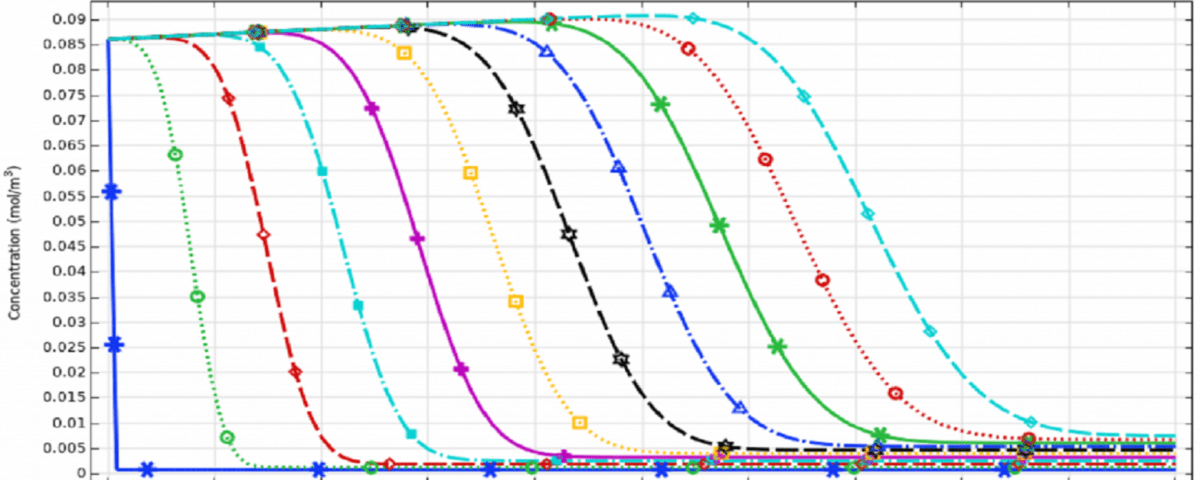

Simulation of the Process of Separating N2 and O2 with COMSOL Software

In this project, the process of separating nitrogen and oxygen from air was simulated using COMSOL software.