Introduction

The growth of the chemical and petrochemical industries has always been driven by the efficient utilization of raw materials and the enhancement of process efficiency. In this context, Unit 02 (NHT) plays a crucial role in the conversion of naphtha into higher-value products.

Naphtha, as a primary feedstock in the petrochemical industry, can be converted into a wide range of products, including benzene. Benzene, as a key raw material in the production of various chemicals such as pharmaceuticals, dyes, and plastics, plays a vital role in the industrial supply chain. Therefore, assessing the feasibility of benzene recovery from naphtha feedstock is of paramount importance to increase value-added and optimize production processes.

Ultimately, it is hoped that this research will be a significant step towards improving production processes and increasing efficiency in the country’s petrochemical industry.

Naphtha Refining Process

Naphtha obtained from crude oil in the distillation unit, which contains sulfur and has a low octane number, is refined in these units using hydrogen gas and in the presence of a nickel-molybdenum catalyst and The sulfur-containing substances are separated as hydrogen sulfide gas.

Unit 02 primarily produces desulfurized heavy naphtha, which is further processed in the catalytic conversion section to increase its octane number.

Unit 12 produces both desulfurized light and heavy naphtha. The heavy naphtha is also sent to the catalytic conversion section for octane enhancement, while the light naphtha is directed to the isomerization unit to remove benzene impurities, linearize hydrocarbons, and improve octane number.

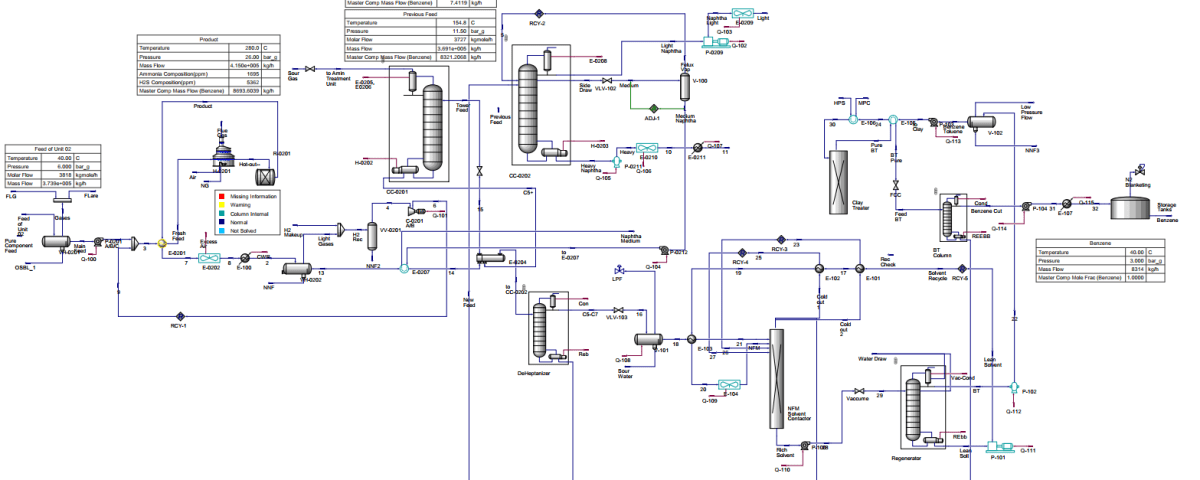

Aspen HYSYS Simulation and Feasibility Study of Unit Benzene Extraction from Naphtha Feed (NHT)

In this project, the BANDAR ABBAS refinery process was initially simulated and calibrated using Aspen HYSYS software, followed by a process analysis. A process was designed to extract a maximum of 8 tons of benzene per hour.

Simulation data was obtained from the refinery’s industrial process diagrams. The economic analysis was not conducted; the evaluation was solely focused on technical and process aspects. The simulation was performed using version 14, and the report is in the original language.